我们的创新

FalconTM

用于现代电弧炉(EAF)工艺优化的无人值守按需氧气测量

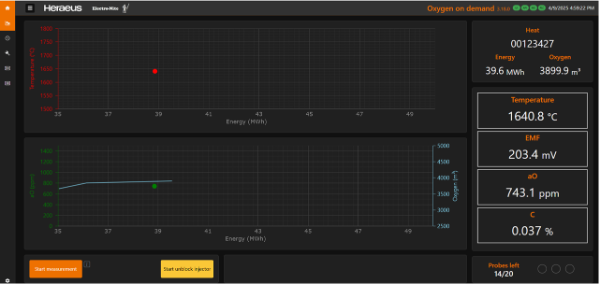

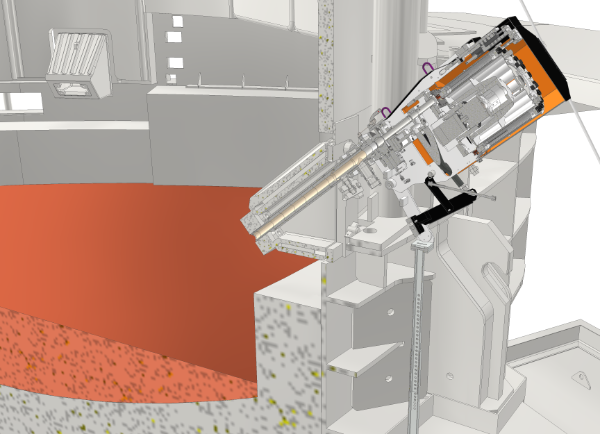

Falcon 是一套自动化测量系统,能够在电炉运行过程中,准确测量液态钢的温度、氧含量和碳含量。它是市场上最快的氧气与温度联合测量系统,专为承受电弧炉周围的恶劣环境而开发。

通过热电偶和氧气传感器,系统能够快速检测氧含量,并将数据发送至 PLC,在用户界面上显示。氧含量的测量帮助操作员准确判断氧气吹炼是否达到终点。

好处

- 提高安全性:该全自动氧气测量系统可从控制室操作,符合当前“无人作业”安全标准。

- 提高产量:早期和多次氧气测量使碳和氧的注入更加可控和精确,从而最大限度地减少铁的过度氧化并降低铁损失。

- 能源效率:Falcon 解决方案在“炉渣门关闭”状态下进行测量,确保在最大泡沫渣状态下实现最佳操作,从而提高系统的能源效率。

- 更低的电力消耗

- 更高效地使用和消耗石墨电极

- 由于电极与钢水之间的热传导改善,耐火材料消耗减少

- 提高质量

- 提供脱磷条件的洞察

- 替代复杂、不可靠且昂贵的机器人

系统信息

Falcon 系统由多个组件组成:

- 机械手:这是一个基于气动的系统,通过滚筒机制供应 Falcon 探头。它确保探头在液态钢中的精确且高效的放置。

- 气动单元:为机械手提供动力,提供操作系统所需的气动力量,使其运行平稳可靠。

- PLC 控制单元:允许从控制室操作整个系统。它管理探头收集的数据,并确保测量的准确性和及时性。

- 设计用于容纳并供应 20 个 Falcon 探头。

- 滚筒的容量支持长时间连续运行,减少了频繁更换的需求。

- 快速更换能力:装有探头的新滚筒可在仅需一分钟内完成更换,确保最小的停机时间和持续运行。

技术参数

|

|

Description |

|---|---|

| Application | Temperature, oxygen and carbon measurement in EAF |

| Measurement input | Two analog inputs |

| Measurement range | |

| Temperature | 1500…1850°C (2732 to 3362°F), type C |

| Oxygen | 150…2000ppm |

| Measurement accuracy | |

| Temperature | ± 10 °C |

| Oxygen | ± 5 mV |

| Calculated values | carbon, aluminum in kg to kill steel, slag %FeO, amount of O2 to reach aO target, steel bath homogeneity (in combination with Chameleon) |

| Different hardware components: | |

| Falcon launcher | |

| Dimensions | 701x1400x422 mm (HxWxD), 140 kg |

| Operating ambient temperature range | -20°C (-4°F) to 60°C (140°F) |

| Air flow: continuously for cooling | 200 l/min |

| Air flow: during the probe launch | 3200 l/min (2900…5000 l/min) |

| Falcon Pneumatic Unit | |

| Dimensions | 1400x800x300 mm (HxWxD), 110 kg |

| Compressed air | 3 to 6 bar |

| Power supply | 24 V DC (from control unit) |

| Falcon Control Unit | |

| Dimensions | 1200x800x400 mm (HxWxD), 120 kg |

| Power supply | 3x400VAC+PE / 50-60Hz / 16 A / max. 4 KW |

| Dust/moisture protection class | IP 54 |

| Level2 communication protocols | Profibus, Profinet, Ethernet IP, Modbus TCP |